Lalas

Star

- Joined

- Nov 8, 2022

- Messages

- 2,129

В Сеченовском Университете открыли единое окно для работы с индустриальными партнерами и бизнесом

Первый Московский государственный медицинский университет имени И.М. Сеченова

February 27, 2024

Partnership & Business

The First Moscow State Medical University named after I.M. Sechenov of the Ministry of Health of the Russian Federation became the first university in Russia to create a single window for working with industrial partners and business. The result of this interaction will be innovative products for implementation in practical healthcare. To implement joint projects, new industrial laboratories are being opened at the University, where products are created and finalized together with high-tech companies.

«Внутри организма заложен гигантский потенциал»: чему посвящен мегапроект «Орган-на-заказ»

Первый Московский государственный медицинский университет имени И.М. Сеченова

February 26, 2024

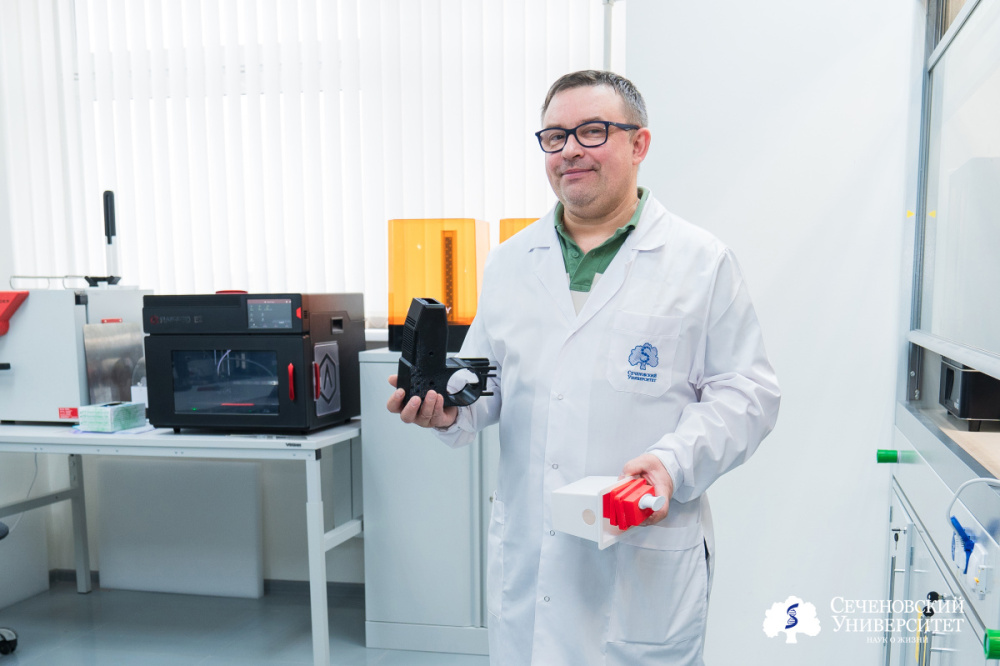

Professor Pyotr Timashev, Scientific Director of the Scientific and Technological Park of Biomedicine of Sechenov University of the Ministry of Health of Russia, told what tissues can be created today with the help of bioengineering, what is the main difficulty in growing them, and what is the goal of the Organ-on-Order megaproject, which was launched this year.

...

— Which organs are currently most in demand from the point of view of transplantology?

— There are no unclaimed organs. Of course, the longest queue today is for kidney transplantation. But, unfortunately, from the point of view of recreating in the laboratory, the kidney is one of the most complex organs. Even getting one full-fledged nephron is not a trivial task, and there are more than a million of them in the kidney. Liver, heart, skeletal tissue... The problem of the shortage of donor material is relevant for all organs.

..

Our specialists of the Center for Innovative Collagen Developments have devoted several years to the creation of an artificial cornea. But in addition to the samples themselves, they have also developed a technology that can be used for mass production. And we are already working on its implementation together with an industrial partner.

— This year, Sechenov University is launching the Organ-to-Order megaproject. What is it aimed at?

— First of all, we need to develop a unified protocol for creating tissues from patient cells. To date, we have developed a number of basic technologies and are now ready to move on to more serious, comprehensive solutions. This is a natural and logical path. In terms of complexity and size, the eardrum cannot be compared with either the liver or the heart. But without understanding the nuances involved in its recreation, it is impossible to move on to the liver or the heart. The concept of the megaproject involves the formation of a technological chain that makes it possible to recreate complex tissues for specific patients on request and complete it with advanced technologies, if necessary. Not in every case it is necessary to grow an organ from scratch and transplant it. Sometimes it is enough to speed up the natural regeneration processes. Such approaches will also be included in the future single protocol. The whole concept of the mega-project is related to the idea that there is a gigantic potential inside the human body. You just need to direct it in the right direction and give it the opportunity to realize.

We already have the technology for such a large-scale project. Now it is necessary to systematize them and build interaction in such a way as to ensure a full production cycle - from a specific request to the formation of a complex of tissues ready for transplantation. And this is an extremely ambitious task. The subprojects cover not only biology and chemistry, but also physics, bionic technologies, and even sociology and law.

— What will be the first steps within the framework of the megaproject?

— The key task now is to create a bioreactor. We need an all-in-one device that can be adapted to specific tasks. If we are growing vessels, we need to achieve the flow of fluid at a certain speed so that this vessel is constantly under the necessary mechanical stress. If we're growing neurons, nerve tissue, they're going to need electrical action. Each individual case requires its own combination of factors, which a conventional bioreactor is simply not able to provide. Therefore, we first need to organize a system that would use mechanical, electrical, and other influences to create the environment necessary for the growth of a particular tissue. We have already begun work on the creation of a bioengineering laboratory that will allow us to implement this task. Then such a bioreactor can be used both for growing bioequivalents and for testing drugs.

— To show the efficiency of the technological chain, it will be necessary to create some kind of organ with its help. What will it be?

— We will start with the periodontal complex. It is a complex structure that includes the tissues that ensure the retention and physiological regeneration of the tooth, namely the cementum of the tooth, the periodontal ligament and the alveolar bone. The biggest challenge is not to grow this or that tissue, but to ensure the connection and simultaneous functioning of several types of tissue. Where the interaction of tissues takes place, we are already talking about completely new mechanical, adhesive, functional properties. And this is a problem that we have yet to solve.

— How long will it take to implement the megaproject?

— Our planning horizon is five years. During this time, we will create a domestic hardware and software complex for a multicell bioreactor, a set of standardized biopaper and bioink for various tasks, develop a technological chain and, most importantly, a standard protocol for creating complex organs to order. But by 2027, we expect to bring the creation of a periodontal complex to the level of clinical practice as the first example of the implementation of our concept."

В дизайн-центре «Биофабрика» появился новый биопринтер для обучения и исследований

Первый Московский государственный медицинский университет имени И.М. Сеченова

March 11, 2024

Sechenov University of the Ministry of Health of the Russian Federation has completed the fourth stream of training under the educational program "Introduction to 3D Bioprinting". This time, the course participants had the opportunity to work not only with the Swedish bioprinter Cellink Bio X6, but also with the Korean Rokit Dr. INVIVO 4D2, which recently appeared in the Biofactory design center.

"Both of these bioprinters are extrusion printers, but they have a different number of print heads, bio ink volumes used and materials available for printing. Unlike the Cellink with 6 print heads, the Rokit has 2 but larger volumes. In addition, the Korean bioprinter has a module for classic extrusion 3D printing with plastic, which allows you to form more durable and voluminous structures. Cellink, in turn, is aimed at the formation of complex structures and interfaces that require the simultaneous use of several types of bioink," explained Polina Bikmulina, head of the Biofactory design center.

The students understood the peculiarities of calibration of both devices, loading and installing cartridges, setting parameters and other aspects of operation. In addition, bioprinters have different software, the mastering of which is necessary to conduct any experiment. All this allowed the students to test biofabrication approaches on different equipment, find out the differences and similarities between different methods, and become more prepared, confident and flexible when planning their bioprinting activities.

The students were employees of the Blokhin National Medical Research Center of Oncology, students and postgraduates of Russian universities. Areas in which participants work include cell biology, including tumor cell biology, materials science, 3D printing, research, and nanoparticle creation.

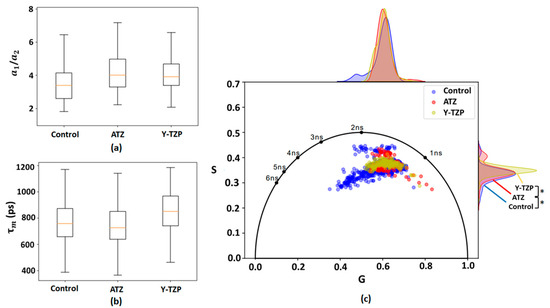

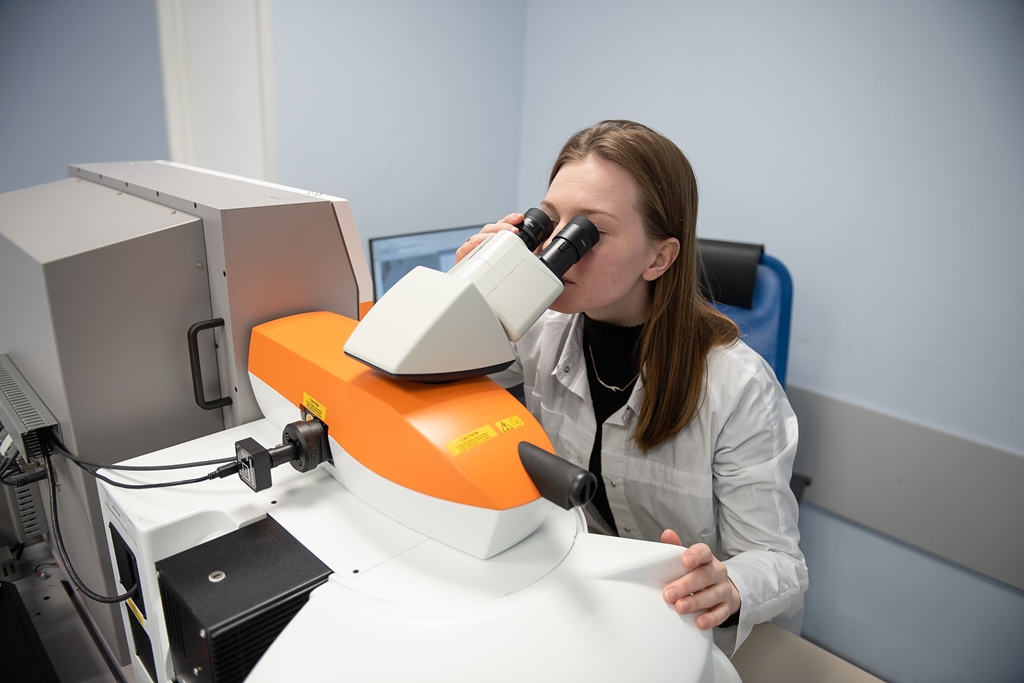

"Interesting and informative lectures allowed us to better understand the features of this direction. At the practical classes, I was able to cover a wide range of 3D bioprinting techniques, get acquainted with several models of 3D bioprinters, and work independently with the devices. Also useful was the block on working with cell cultures: growing cells, cell spheroids, preparing spheroids for 3D bioprinting, characterizing spheroids using fluorescence microscopy, LIVE/DEAD test. The knowledge gained will help me to start my first experiments on a 3D bioprinter that is in our laboratory. And also, of course, it's great that now I personally know colleagues experienced in this field, who will always be able to help with advice or share knowledge," said Pavel Shakhov, a PhD student at MEPhI, one of the listeners.

***

Last edited:

.png)